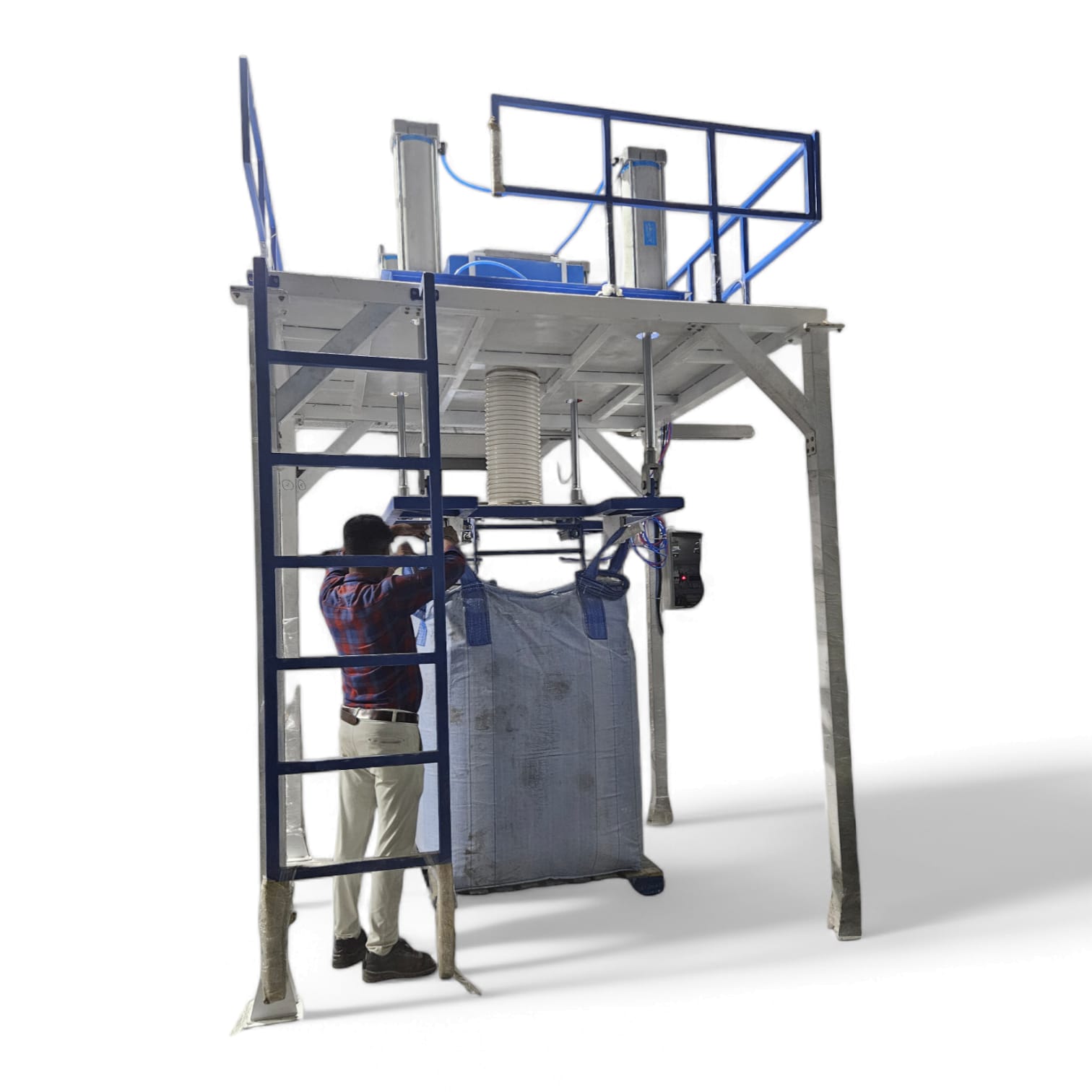

JUMBO BAG PACKAGING MACHINE

₹665,000.00

| Bagging Speed | 4-5 Ton per hour |

| Display Resolution – Selectable | 100 gram |

| MOC – Contact Parts | Contact parts – S S 304 – Machine non contact parts MS |

| MOC – Structure & supports | MS – 7 tank processed Powder Coated |

| Bagging system | Type – Electro Pneumatic

Model – SAMIRIKA jumbo pac, Speed – 4-5 Ton Per Hour Weighing – 2000 kg capacity Weighing – Loadcell based, 500 kg X 4 Nos loadcell, Structure – 100*100*3 mm SQ pipe with safety rails and ladder Pneumatic tubbing – PU. |

| Jumbo Bag lifting system | Automatic, pneumatic operation, heavy duty cylinder with flow control & additional Air Tank |

| Controller | 24 Bit ADC, programmable, RS 485 Mod- bus com port, multi leval

Paaswords, I/O free define, built in Counter & totalizer, Auto tare Enable /Disable, Auto weight correction in each bag, Individual under & over weight Tolerance checking in each bag with Alarm output, 7 inch colour touch screen, IP 65@ panel mount, Built in Data logging, Bag count, Total weigh |

| Control panel | M S Box, with necessary wirings & accessories, panel & machine

Internal cables – copper flexible with require core and size |

| Junction Box | MOC – MS powder coated |

| Support structure | MS Powder coated, 100*100*3 mm MS pipes

Safety Rails – 25 mm pipe, Base plate 8 mm Require cross supports |

Purchase Note –

Price Varied based on Customization